What is FIBRETRON REBAR ?

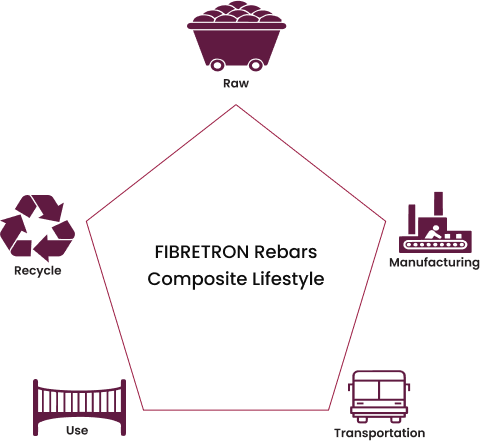

FIBRETRON rebars are Glass Fibre Reinforced Polymer (GFRP) Rebars that are a lightweight, high-strength and corrosion-resistant alternative to traditional steel reinforcement bars. FIBRETRON rebars are made of composite material, which comprises of high strength glass fibers embedded in a polymer resin matrix.